Treatment Facility at GCB Cocoa

McKinCo Project Case Study

Treatment Facility at GCB Cocoa

- Glemsford, Sudbury

- November 2022

McKinCo recently designed and built a number of panels for a new effluent treatment plant at GCB Cocoa.

Initially a temporary pump control panel was supplied consisting of DOL starters for a couple of raw effluent transfer pumps, controlled using hardwired relays rather than a PLC system. This panel was to control operation during the migration to the new treatment system.

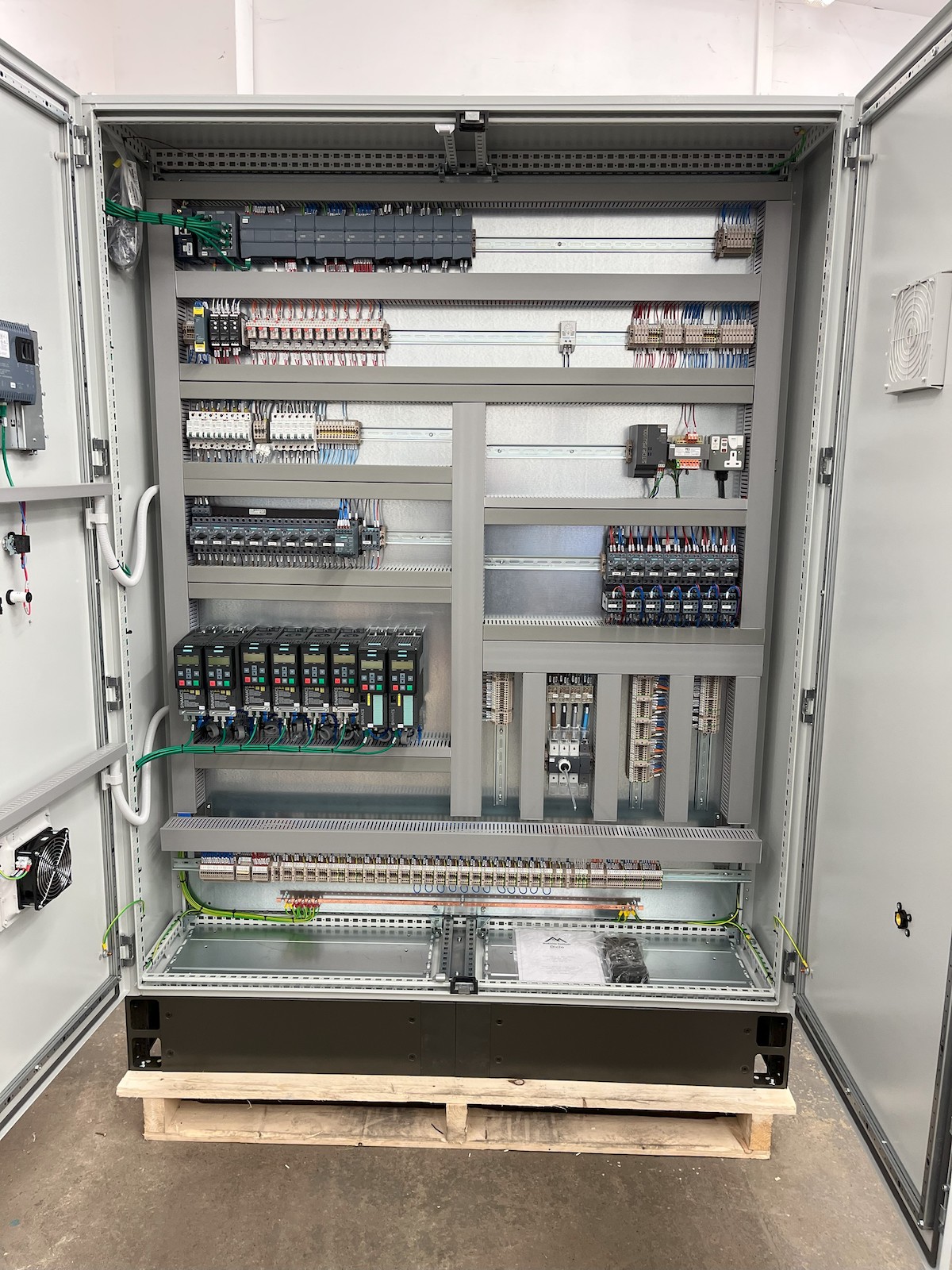

The main control panel, housed in a large floor standing thermostatically controlled mild steel enclosure, utilised a Siemens S7-1500 PLC alongside a Siemens 12” TP1200 Comfort touchscreen HMI to control the treatment plant. It also included multiple Siemens G120 / G120C VSDs, Siemens 3RW30 Softstarters and DOL Starters for the various pumps, dosing pumps, mixers, scrapers, compressors & heaters being controlled.

In addition, it included an Ewon Flexy industrial internet data gateway to allow remote access and send email alerts and notifications to the operator.

A single 3P+N ‘8 way’ Panel board (800A) and a 1P+N ’10 way’ Distribution board (100A) were also supplied. These boards were used to supply various loads around the site such as our main control panel, large blowers and small power & lighting.

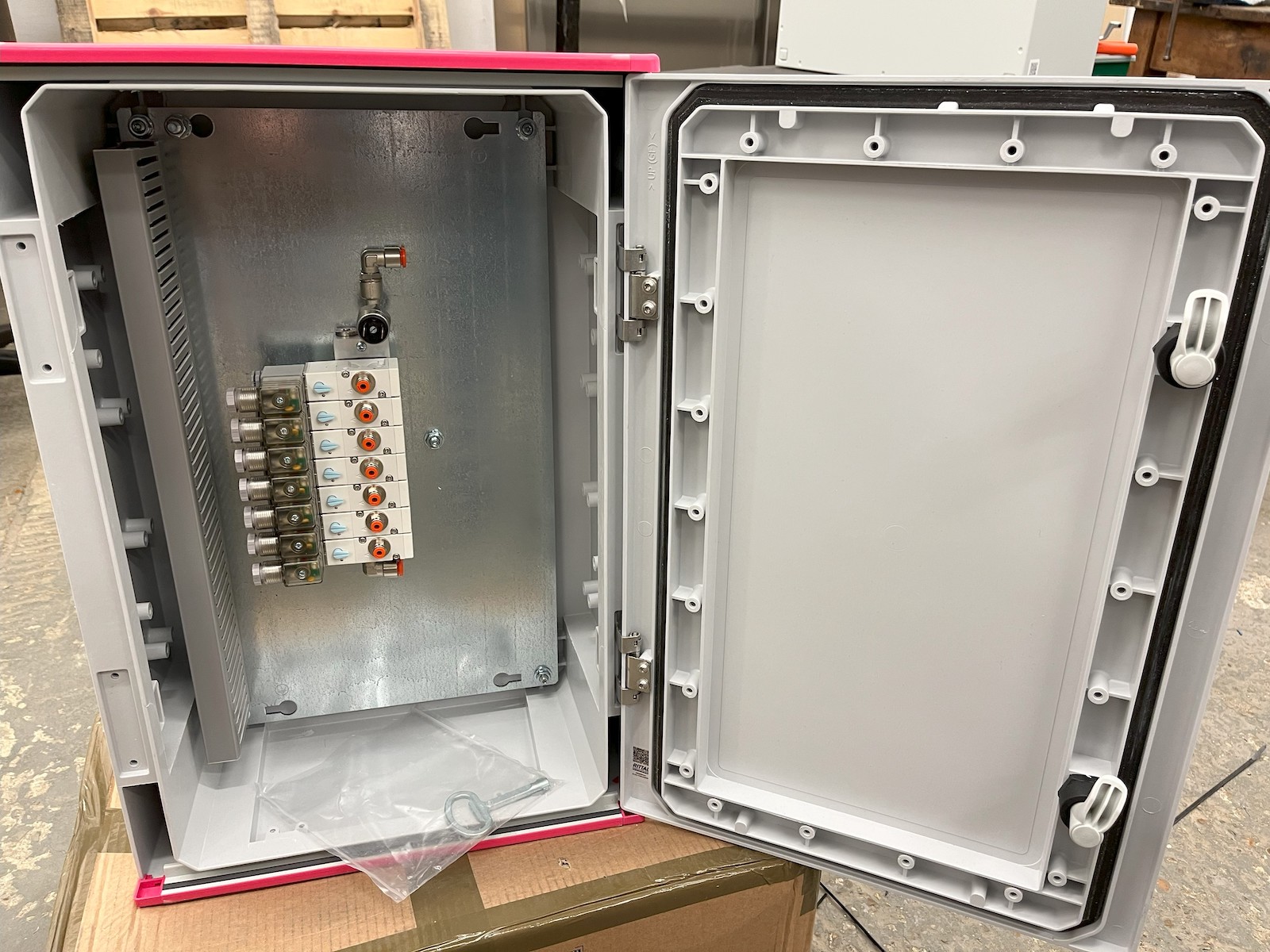

The final panel supplied on this project was a solenoid panel. This wall mounted, mild steel enclosure contained seven pneumatic solenoid valves mounted on a 7-station manifold, complete with pressure switch and associated pneumatic fittings.

Have a Control Panel project like this?

Request a Free Quote

Please reach out to a member of the McKinCo Team